Agency Highlight #1: Vallejo Flood and Wastewater District

This website post is the first in a series of posts to highlight Bay Area Biosolids Coalition (BABC) member agencies, particularly showcasing their solids treatment processes, operational challenges, and other solids related information.

Background

The Vallejo Flood and Wastewater District (VFWD) was established in 1952 by the State of California as an independent special district and is responsible for maintaining storm drainage, wastewater collection, and wastewater treatment systems within its service area. The VFWD serves a population of approximately 120,000 people within the City of Vallejo and other adjacent unincorporated areas.

The VFWD Wastewater Treatment Plant (WWTP) began treating Vallejo’s sewage in 1959 and currently has a facility permitted flow of 15.5 million gallons per day (mgd) of average dry weather flow (ADWF). The VFWD WWTP is located at 450 Ryder Street, Vallejo, California. Figure 1 shows an aerial map of the VFWD WWTP, discharge points, and Tubbs Island, where VFWD land applies their biosolids.

Source: NPDES Permit R2-2023-0001

Figure 1: Facility and Outfall Locations

Solids Treatment Train

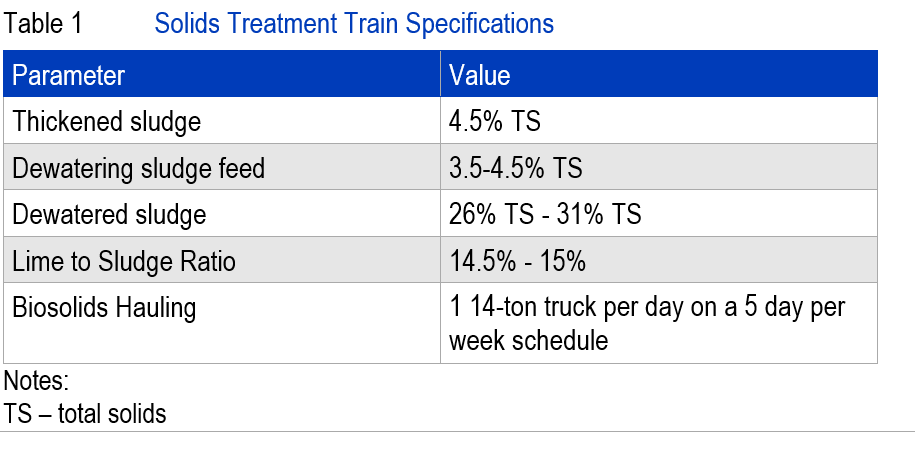

Figure 2 shows a process flow diagram of the solids processes at the VFWD WWTP. The solids treatment train consists of co-settling in primary clarifiers, or thickening with gravity belt thickeners, lime stabilization, and dewatering with belt filter presses.

Figure 2: VFWD WWTP Process Flow Diagram

Primary sludge and waste activated sludge (WAS) are co-settled in the primary clarifiers. Since primary sludge and WAS co-settle, the gravity belt thickeners only operate when needed. Thickened solids are lime stabilized to meet the 40 CFR Part 503 pathogen reduction requirements by raising the pH of the solids. The VFWD batches its own lime for the lime stabilization process. The VFWD noted that the lime stabilization process has both benefits and disadvantages. One of the benefits is that it is a quick process (2-hour batch process). One of its downsides is required regular cleaning (approximately every 6 months) and maintenance to remove any lime accumulation or buildup, which could have a negative impact on the belt filter presses and other processes. Currently, the VFWD plans to continue lime stabilization going forward and is not considering altering this process unless there is a driver to produce Class A biosolids or treat for PFAS. Table 1 provides further data regarding the VFWD WWTP solids process.

Land Application of Biosolids at Tubbs Island Farm

The VFWD has land applied its biosolids at Tubbs Island (shown in Figure 3) for over 20 years. The first test plot was conducted in 1978, and in 1983, the VFWD purchased Tubbs Island and the associated farm for biosolids beneficial use. Historically, the soil at the Tubbs Island land application sites was acidic. However, due to the regular application of VFWD’s lime stabilized biosolids over time, the pH of the soil has increased resulting in increased crop yields and ability to grow a wider variety of crops.

Figure 3: Tubbs Island Farm

Due to economic feasibility and proximity of Tubbs Island to the WWTP, VFWD conducts its own biosolids hauling using two district-owned super dump trucks (each with a capacity of 14 tons) and two dedicated truck drivers to conduct the hauling. Under normal conditions, the VFWD hauls 1 load per day on a 5 day per week basis. Under higher load conditions, multiple loads are hauled each day. The WWTP has a cake storage hopper with adequate capacity (95 tons) to store biosolids over the weekend.

Hauled biosolids are temporarily stockpiled on a storage pad and subsequently spread and incorporated into the soil as a soil amendment for agricultural crop production. The storage pad is made of compacted, lime-stabilized earth, surrounded by a berm to avoid runoff. VFWD hauls approximately 12,000 wet tons per year, and the storage location has sufficient capacity to store an entire year’s worth of VFWD biosolids.

The VFWD has a contract with a single farmer. The farmer land applies biosolids every September (and also July in the last two years) at or below the agronomic rate. Biosolids are applied in a rotating schedule where each of five fields gets land applied every 5 years. A third party is contracted to spread the biosolids, and the farmer subsequently disks in the solids to meet vector reduction requirements. Figure 4 shows a photo of grain crops (i.e., wheat, oats, barley, rye grass) grown in Tubbs Island, which are mainly used as animal feed.

VFWD’s economic analysis estimates the biosolids hauling and land application process costs approximately $11-$12 per wet ton.

Figure 4: Grain grown with VFWD Biosolids

Biosolids to Lystek

In addition to land application at Tubbs Island, VFWD sends a small portion of its biosolids to the Lystek Organic Material Recovery Center located at the Fairfield Suisun Sewer District (FSSD) WWTP in Fairfield, California. Starting in late 2019, VFWD sends approximately 1 load per week to the Lystek Facility where it is processed into Lystek’s biosolids-derived liquid fertilizer. The VFWD began sending a portion of their biosolids to Lystek to increase their biosolids management resilience due to a temporary Highway 37 closure from the nearby wildfires in 2019, which restricted VFWD’s access to land apply on Tubbs Island. VFWD’s contract with Lystek provides greater flexibility as an additional end-use option which would allow them to quickly pivot to hauling 100% of their biosolids to Lystek if ever needed.

Challenges

Levy Maintenance - One of the challenges at Tubbs Island has been maintaining the integrity of the levies. The levies were not constructed according to Army Corps of Engineers standards. Recently, VFWD has seen more erosion and increases in annual levee inspection, maintenance, and repair activity.

Contaminants of Emerging Concern - VFWD has participated in recent studies and research partnerships. Uncertainties surrounding future findings and ongoing research on the topic of contaminants of emerging concern like PFAS may be a significant risk in the future.

Sea Level Rise - Tubbs Island is located along the San Francisco Bay and may be at risk of flooding from sea level rise. Sea level rise analysis of Tubbs Island has been integrated into broader San Francisco Bay sea level rise analyses, such as “Adapting to Rising Tides Bay Area Sea Level Rise Analysis and Mapping Project” (2017).

Farmer Contracts - VFWD noted that the transition periods between farmer contracts may be difficult depending on the level of interest for the contract.

Future Plans

VFWD has been actively involved in research with Baylands groups, habitat restoration groups, and additional ongoing projects with environmental non-profits like Audubon. VFWD will continue with these studies and are open to more habitat restoration projects in the future. Also, VFWD is exploring the possibility of utilizing additional biosolids application capacity at Tubbs Island to pursue potential regional biosolids land application partnership opportunities in the future.

Acknowledgements: Thank you to Jennifer Harrington, Orlando Cortez, Michael Smith, and Johnson Ho from VFWD for sharing information and resources to write this post.

Sources:

NPDES Permit: R2-2023-0001.

VFWD Brochure. https://thehawkinscompany.com/wp-content/uploads/2019/09/vallejo_fdir_brochure_v3.FINAL_.pdf

VFWD Historical Timeline (1952-2012). https://www.vallejowastewater.org/DocumentCenter/View/248/District-Historical-Timeline-PDF

VFWD Website - Biosolids page. https://www.vallejowastewater.org/237/Biosolids

Adapting to Rising Tides Bay Area Sea level Rise Analysis and Mapping Project. September 2017. https://www.adaptingtorisingtides.org/wp-content/uploads/2018/07/BATA-ART-SLR-Analysis-and-Mapping-Report-Final-20170908.pdf